Harvesting algae

Harvesting algae after its growing cycle is the first step in processing it into biofuel in a commercial process. Harvesting techniques depend on the type of algae used. Generally it involves two main processes: bulk harvesting and thickening. After harvesting the algae, it must be dried.

Bulk Harvesting

This method aims to separate the algae biomass from the growing solution. This usually begins with flocculation; adding chemicals to clump the suspended algae particles within the growing solution into bigger clusters (see figure 1). Various chemicals can be used for flocculation. The type of flocculant used will depend on the type of algae being produced the processs used to grow and convert the algae to a biofuel.[2]

Flocculation is followed by collecteing the clumped algae. This can be done by one of three methods:

- Filtration - using filters to capture and remove the clumped algae.

- Flotation - sending air bubbles to bring the algae clumps to the surface.

- Gravity sedimentation - using time and gravity to bring the algae clumps to the bottom.

Many variations of each process exist, which involve the addition of chemicals, pressurized apparatus or combined processes.[2]

Thickening

Thickening aims to concentrate the biomass after it is separated. This can be accomplished by using centrifugal forces, addition of chemicals, or using ultrasonic radiation.[2] In using centrifugal forces, the more dense component moves farther away from the spinning point, while the less dense component stays closer.

The idea is to continuously collect the algae without disturbing the growing cycle, to harvest an algae biomass with a low water content and to use the least amount of time, space, and money.

Dewatering

Dewatering involves removing the water from the collected algae so that further processing is possible and efficient. There are two approaches to this concept:

Drying by External Heat

Currently, drying algae using external heat is not economically feasible because of high costs. The process requires large amounts of time, space and money and as a result the costs are larger than any profits that could be earned.[3] A few methods of drying are sun drying, spray drying, shelf drying, drum drying and freeze drying.

Dewatering by Other Methods

There are many companies currently researching techniques to improve the dewatering process of algae. Below are two examples:

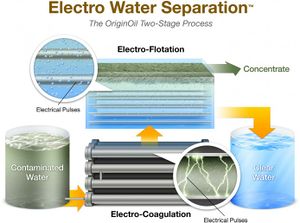

OriginOil, has a patent-pending electro-water separation device which can remove organic material, which includes algae, from water without the use of chemicals. The process involves sending electric pulses into the mixture to clump the algae and bring the clumps to the surface.[5]

AlgaeVenture, has introduced a solid-liquid separation model that separates materials using a conveyor belt system. The equipment uses the properties of adhesion and cohesion to separate algae from other materials used in the algae growth process. Adhesion is the tendency of different surfaces to cling to one another, while cohesion is the tendency of similar surfaces to cling to each other.[6]

The methods outlined above are only a few of the many processes used to harvest algae for biofuel production. Harvesting and dewatering the algae often go hand in hand. Many processes collect the algae from the growing cycle through dewatering. There are also many new processes which are still in development.

For Further Reading

- Biofuel

- Algae

- Biomass

- Processing algae

- Or explore a random page

References

- ↑ BYU Engineering and Technology "basic steps of flocculation" [Online]. Available: http://www.et.byu.edu/~wanderto/homealgaeproject/Harvesting%20Algae.html

- ↑ 2.0 2.1 2.2 L. Brennan, P. Owende “Biofuels from Microalgae”, Science Direct, [Online] February 2010, http://www.sciencedirect.com/science/article/pii/S1364032109002408 (Accessed: 31 October, 2013)

- ↑ Quantitative Uncertainty Analysis of Life Cycle Assessment for Algal Biofuel Production. Deborah L. Sills, Vidia Paramita, Michael J. Franke, Michael C. Johnson, Tal M. Akabas, Charles H. Greene, and Jefferson W. Tester. Environmental Science & Technology 2013 47 (2), 687-694

- ↑ OriginOil 2013 "Electro Water Separation" [Online]. Available: http://www.originoil.com/products/electro-water-separation

- ↑ “Electro Water Separation”, OriginOil, [Online] 2013, http://www.originoil.com/products/electro-water-separation (Accessed: 31 October, 2013)

- ↑ “Unique Solid-Liquid Separation Lab Equipment Introduced by AlterE Technologies”, PRWeb, [Online] September 2010, http://www.prweb.com/releases/AlterE/Separation/prweb4591484.htm (Accessed: 31 October, 2013)