Natural gas refueling station

Natural gas refuelling stations are places to refuel Natural gas vehicles (NGVs) that look similar to those for diesel or gasoline.[2] The refueling process of natural gas depends on whether compressed natural gas (CNG) or liquefied natural gas (LNG) is being used. A CNG station requires more equipment however an LNG station requires more safety precaution while fueling since it is stored at extremely cold temperature.[3] There are about 24,000 natural gas refueling stations in the world. China contains roughly 20% of them. Most of the fueling stations are CNG stations with just few LNG ones.[4]

CNG refueling station

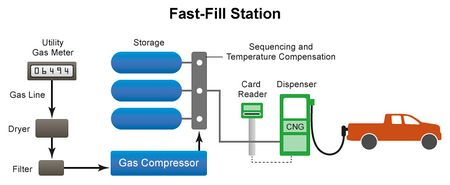

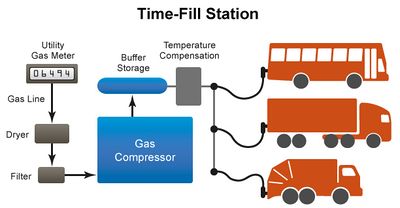

A CNG fueling station consists of a compressor, a gas dryer, storage vessels, dispensers and underground piping.[3] Usually a CNG stations are installed where there is already a natural gas pipe in the ground. There are two main types of CNG refueling systems: fast-fill and time-fill.

Fast-fill station

A fast-fill station fills a vehicle within 3-5 minutes—about the same speed as a standard gasoline pump. This is a good system for light duty vehicles (pickup trucks, vans, sedans) when they need normal consumer filling. The stations get their natural gas from a local pipeline that is initially at low pressure. Then it is compressed on site and moved to storage vessels at the fueling station. CNG is often stored in vessels at high pressure around 4300 psi.[5] CNG vehicle operators use dispensers to fill their vehicles. The dispensers measure the pressure and temperature at which the fuel is being transferred to ensure the tank is not overfilled.[5]

Time-fill station

A time-fill system fills a vehicle over a period of time, often overnight when the vehicle is not in use. This type of fueling is primarily designed for fleets (such as transit buses, taxis, cargo trucks) where a station is built at the fleet location and one can fill all vehicles at once when they are not being operated. Time-fill system can also be used for small applications where a station is built in the garage of a driver’s house. Time-fill stations have no storage tanks but they have large compressors from which vehicles are directly being filled. They operate at lower pressure than that of fast-time filling. Also, stations have a buffer tank which purpose is to prevent the compressor from turning on and off all the time. With the less equipment needed, this type of fueling stations is less expensive since it requires lower capital and maintenance cost. The time spent to fill a vehicle depends on the number of vehicles being fueled and the size of compressors. Vehicles with larger tanks need larger compressors.[5]

LNG refuelling station

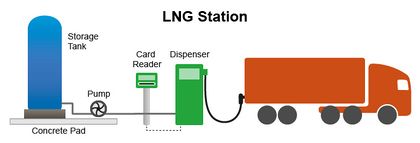

LNG stations are very similar to gasoline (petrol) ones because they both are liquids. Natural gas is delivered to the station location and stored in special tanks at a very low temperature (about -160°C) in order to stay in the liquid phase. Then LNG is pumped via a dispenser to the vehicle. Due to the low temperature, special training is needed to handle LNG and protective gloves and face shields must be worn to avoid freezing burns. Also, LNG is stored in cryogenic tanks usually constructed from stainless steel with multi-layer insulation to prevent heat to leak into the cold LNG. LNG fueling takes about the same amount of time as diesel or gasoline.

Other refueling station

Other types of fueling stations include Liquid-Compressed Natural Gas (LCNG), which is basically a combination of both liquefied and compressed natural gas, and Vehicle Refueling Appliance (VRA) which is a small unit designed to fill light vehicles such as lift trucks.[2]

For Further reading

- Natural gas vehicle

- Compressed natural gas

- Liquefied natural gas

- Alternative fuel vehicle

- Or explore a random page

References

- ↑ File:FillingUpCNG.jpg - Wikimedia Commons", Commons.wikimedia.org, 2018. [Online]. Available: https://commons.wikimedia.org/wiki/File:FillingUpCNG.jpg. [Accessed: 13- Jun- 2018].

- ↑ 2.0 2.1 NGV Global Knowledge Base, "Refuelling NGVs", 2013. [Online]. Available: http://www.iangv.org/refuelling_ngvs/ [Accessed 20 October 2013].

- ↑ 3.0 3.1 Cummins Westport, "Fuel Station Providers ", 2013. [Online]. Available: http://www.cumminswestport.com/links/fuel-station-providers [Accessed 20 October 2013].

- ↑ "Compressed natural gas - an overview | ScienceDirect Topics", Sciencedirect.com, 2018. [Online]. Available: https://www.sciencedirect.com/topics/materials-science/compressed-natural-gas. [Accessed: 14- Jun- 2018].

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 U.S. Department of Energy, Energy Efficiency & Renewable Energy (EERE), Natural Gas Fueling Infrastructure Development, (2013). [Online]. Available: http://www.afdc.energy.gov/fuels/natural_gas_infrastructure.html [Accessed 19 October 2013].