Spacers

Spacers are small pieces of plastic or metal that work to separate and support the two (or three) panes of glass in a multi-glazed window. These spacers hold the panes in place, thus creating an air space filled with noble gasses such as argon or krypton in gas filled windows.[2] Spacers are a vital part of every window unit as they promote the structural integrity of the window while promoting the thermal and moisture seal of the window, increasing its effectiveness. The quality of these seals also increases the insulating abilities of the window.[2]

High quality spacers are durable, strong, and have high insulating abilities. Ensuring that spacers meet these specific qualifications is determined by which type of material is used to build the spacer itself, and each material has its benefits and drawbacks. When a high quality spacer is used along with gas fillings and e-coated windows, energy efficiency of the window itself can be greatly improved.

Composition

Most spacers are composed of some kind of metal or a plastic/foam. The metal spacers are stronger and more durable than foam spacers, but may be less thermally efficient than an insulating foam.[2] In addition, aluminum spacers have been known to cause issues such as glass fogging and moisture buildup due to their inability to regulate temperature as well as other materials.[3] Spacers also generally include a drying agent known as a desiccant to absorb any moisture that enters the window.[4]

New types of spacers are being developed to increase the performance of the spacer and maximize efficiency. At the moment, flexible spacer are among the most energy efficient types of spacers. They are generally more insulating than metal spacers and offer less condensation build up, better R-values (and therefore better insulating properties), and good noble gas seals. These seals also provide more soundproofing than other seals.[3]

Along with the spacer itself, organic sealants are used to provide structural support and act as a moisture barrier.

Function

In addition to providing structural support to a window, spacers also perform a series of other important functions. Such functions include:[4]

- Accomodate stresses due to the expansion of the window pane due to changes in temperatures as well as warping due to pressure differences. When temperatures are warmer, a flexible spacer allows for expansion and allows for contraction in colder weather. The flexibility of the spacer ensures that the sealant does not crack or break, ensuring that the seal on the window is as strong as possible.[2]

- Provide a moisture barrier to prevent water or water vapour leakage into the home or the window, which would cause fogging. Generally speaking, foam spacers are more effective at preventing vapour buildup inside of the window.[5]

- Provide a tight seal to prevent the insulating gas on the inside of the window cavity from leaking out.

- Provide good levels of insulation to ensure furnaces and air conditioners do not have to work as hard to regulate the temperature in a space by reducing heat loss. As well this reduces condensation from forming on the window by regulating the temperatures of the panes.

Types of Spacer Systems

Although spacers perform the same functions in all windows, there are two major ways to assemble these spacers that provide different levels of sealing and durability. The two main systems of spacers used in multi-pane window systems are single-seal and double-seal.[4]

Single-Seal

Single-seal systems are assembled in the way their name indicates - with a single seal. In this type of system an organic butyl sealant is applied at the bottom of the spacer. This holds the window together and prevents moisture from entering the window to a certain degree. These seals are strong, but generally not air-tight enough to be effective in gas filled windows where gas leakage poses a serious problem.[4]

Double-Seal

Double-seal systems provide a higher level of seal than single-seal systems, as the contain both a primary and secondary sealant. The primary sealant, again an organic butyl compound, seals the spacer to the glass itself to prevent water intrusion and gas loss. The secondary silicone sealant then provides the structural strength to the window. For windows with e-coatings, the coating on the area where the seal is must be removed for the seal to be effective.[4]

For Further Reading

- Fenestration

- Windows

- Building envelope

- Glazing

- Insulator

- Low emissivity coating

- Or explore a [random page]

References

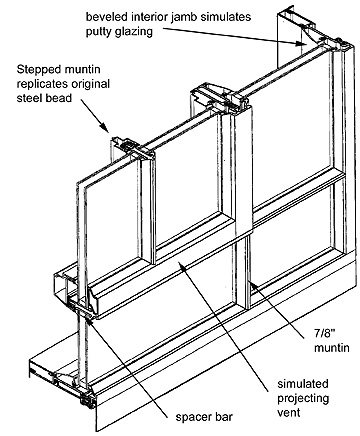

- ↑ "Isometric drawing of aluminum window". Licensed under Public Domain via Wikimedia Commons - http://commons.wikimedia.org/wiki/File:Isometric_drawing_of_aluminum_window.jpg#/media/File:Isometric_drawing_of_aluminum_window.jpg

- ↑ 2.0 2.1 2.2 2.3 PGG Glass Technologies. (March 29, 2015). Stainless Steel Spacer System [Online]. Available: http://www.ppgresidentialglass.com/other_glass/intercept.aspx

- ↑ 3.0 3.1 Wakefield Equipment. (March 29, 2015). Energy Efficient Window Glass Spacers [Online]. Available: http://wakefieldequipment.com/window-spacers-and-energy-efficiency/

- ↑ 4.0 4.1 4.2 4.3 4.4 Efficient Windows Collaborative. (March 29, 2015). Low Conductance Spacers [Online]. Available: http://www.efficientwindows.org/spacers.php

- ↑ Super Spacer. (March 29, 2015). What Type of Spacer is in my Windows? [Online]. Available: http://www.expertwindows.ca/docs/SuperSpacercomparison_brochure_1330055938.pdf