Uranium enrichment

Uranium enrichment is a process that is necessary to create an efficient nuclear fuel out of mined uranium by increasing the percentage of uranium-235 - which undergoes fission with thermal neutrons. Although many reactors require enriched fuel, the Canadian-designed CANDU and the British Magnox reactors use natural uranium as their fuel.[2]

Nuclear fuel is mined from naturally occurring uranium ore deposits, and the uranium in this ore is isolated through chemical reactions and separation processes. In its isolated form, the uranium is known as yellow cake and has the chemical formula U3O8. However, naturally occurring uranium does not have a high enough concentration of 235U - only about 0.72% - with the remainder being 238U.[3] Since uranium-238 doesn't undergo fission with thermal neutrons, the amount of uranium-235 must be increased before it can be effectively used as a nuclear fuel. The purpose of uranium enrichment is to increase the percentage of the uranium-235 isotope with respect to others, with a necessary percentage of around 4%.[3]

Enrichment Processes

Most reactors, including the common light water reactor (both PWRs and BWRs), cannot run on natural uranium as its uranium-235 concentration is so small. Enrichment generally requires physical processes rather than chemical processes, and the goal is to increase the amount of uranium-235 to 3-5%.[4] Enrichment requires uranium to be in a gaseous form, and the simplest way to achieve this is to convert it to a different chemical known as uranium hexafluoride. The process of changing uranium oxide concentrate to uranium hexafluoride takes place at a conversion plant - the first stopping place for uranium after it leaves a mine. In the first two processes, only a small amount of isotope separation happens at a time so repeated separations are done successively, arranged in a cascade.

Gaseous Diffusion

For many years the main process was gaseous diffusion, wherein the yellow cake uranium was chemically transformed into uranium hexafluoride (UF6). This chemical is in its solid form under normal conditions, but transforms into a gas if the temperature is raised slightly or the pressure is lowered.[3] Since the 235UF6 molecules are slightly lighter than the 238UF6 molecules, they move more quickly as a gas through diffusion. Thus if uranium hexafluoride is passed through a very long pipe, the gas that emerges at the far end of the pipe will have a slightly higher percentage of 235U. However, the pipe must be extremely long as the lighter 235UF6 diffuses only 0.43% faster than 238UF6.[3] Because of this, the method of gaseous diffusion is not widely used anymore.

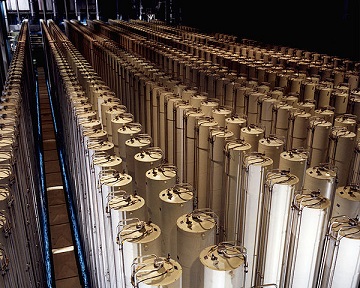

Gas Centrifuges

Today, enrichment is achieved using a gas centrifuge. The separation process here relies on the mass difference of the molecules (see gaseous diffusion above). Here, uranium hexafluoride is fed into an evacuated cylinder containing a rotor. When these rotors are spun at a high speed, the heavier 238UF6 collects near the walls of the cylinder while the slightly lighter 235UF6 collects near the central axis. The enriched product is then drawn off. This method is preferred over gaseous diffusion as it requires only about 3% of the power to separate the uranium.[3] A centrifugal separation method is much more energy-efficient than diffusion, as it requires only about 50-60 kWh per SWU (separative work unit, which is the amount of separation done by an enrichment process).[2] Additionally, these plants can be smaller as they don't require an extremely long pipe. For efficient separation to occur, these centrifuges must rotate quickly - generally at 50 000-70 000 rpm.[4]

Although centrifuges hold less uranium than a diffusion stage, they are able to separate isotopes much better. Centrifuge stages generally are composed of a large number of centrifuges in parallel, forming a cascade.

Laser Isotope Separation

The use of lasers in a separation process is still being developed. This separation technique requires lower energy input and other economic advantages. In this process, a laser with a very specific frequency interacts with a gas or vapour. Since the frequency has an associated energy, the interaction of the beam with the gas allows for the excitation or ionization of certain isotopes in the vapour. With this excitement, it may be possible to separate molecules containing a specific isotope to collect only the excited isotope.[4]

Depleted Uranium

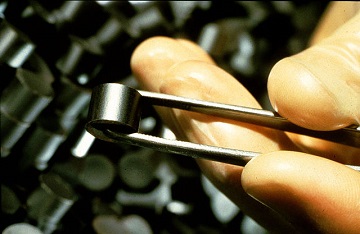

Once the uranium has been enriched, it is converted back into an oxide - UO3 - and compressed into small nuclear fuel pellets. The uranium left over from this process is referred to as depleted uranium. This depleted uranium is extremely dense and poses a low radiological danger, so it is frequently used in counterweights or radiation shielding. If combined with nitrogen, depleted uranium can form a hard, dense material known as uranium nitride. This uranium nitride is used as a coating for armour piercing shells.

Environmental Issues

Most enrichment processes involve only natural, long-lived radioactive materials. Uranium is only weakly radioactive, but its chemical toxicity is more significant . Thus protective measures required for an enrichment plant are similar to those in other chemical industries. When exposed to moisture, uranium hexafluoride forms a very corrosive acid - hydrofluoric acid. Any leakage of this chemical is undesirable and to prevent this almost all areas of an enrichment plant keep the uranium hexafluoride gas below atmospheric pressure.[2] This stops any outward leakage. Additionally, double containment is provided in areas where higher pressures are required and venting gases are collected and treated.

Enrichment accounts for around half of the cost of nuclear fuel and 5% of the cost of the electricity generated. Previously enrichment has been the main source of greenhouse gases from the nuclear fuel cycle as electricity used for enrichment was generated using coal. Although there are associated greenhouse gas emissions, it is only about 0.1% of the emissions of an equivalent coal-fired power plant.[2]

References

- ↑ Wikimedia Commons. (June 17, 2015). Fuel Pellet [Online]. Available: https://commons.wikimedia.org/wiki/File:Fuel_Pellet.jpg#/media/File:Fuel_Pellet.jpg

- ↑ 2.0 2.1 2.2 2.3 World Nuclear Association. (June 17, 2015). Uranium Enrichment [Online]. Available: http://www.world-nuclear.org/info/Nuclear-Fuel-Cycle/Conversion-Enrichment-and-Fabrication/Uranium-Enrichment/

- ↑ 3.0 3.1 3.2 3.3 3.4 Jeff C. Bryan. (June 17, 2015). Introduction to Nuclear Science, 1st ed. Boca Raton, FL, U.S.A: CRC Press, 2009.

- ↑ 4.0 4.1 4.2 Ian Hore-Lacy. (June 17, 2015). Nuclear Energy in the 12st Century, 1st Ed. Burlington, MA, U.S.A: Elsevier Inc, 2006.

- ↑ Wikimedia Commons. (June 17, 2015). Gas Centrifuge Cascade [Online]. Available: https://commons.wikimedia.org/wiki/File:Gas_centrifuge_cascade.jpg#/media/File:Gas_centrifuge_cascade.jpg