CANDU reactor

CANDU reactor is a type of nuclear reactor which was developed in Canada, and is currently used in nuclear power plants for electrical generation in various countries around the world. CANDU stands for CANada Deuterium Uranium, which reflects the key role of deuterium, or heavy water, which acts as the reactor's neutron moderator, a unique trait of the CANDU.[2] The reactors are also different from other reactors because they are designed to utilize natural uranium as a fuel (as opposed to enriched uranium).[3]

The use of these reactors in power plants in Canada provide the country with around 15% of its total electricity with 19 currently in operation.[4][5] 12 CANDU reactors are also in use in China, South Korea, Romania, India, Pakistan and Argentina.[5]

Characteristics

Fuel

CANDU reactors use natural uranium as their nuclear fuel. Natural uranium is composed of about 0.7% uranium-235, and the remaining 99.3% is mostly uranium-238 which cannot directly be used in a fission process to obtain energy.[7] The uranium-238 is fertile and can absorb high speed neutrons and convert to plutonium-239 which is fissile and then undergoes fission; this process accounts for around half of the energy produced within the reactor.[8] CANDU reactors use about 25 to 30% less mined uranium than a comparable light water reactor (mostly because of the better use of neutrons in the reactor).

In CANDU reactors, fuel in the form of uranium oxide powder is packed into pellets and placed in the fuel rods. Thirty seven fuel rods are bunched together to complete a cylindrical fuel bundle, seen in Figure 2. The fuel bundle is approximately 50 cm in length and 10 cm in diameter.[9] A fuel bundle remains in the reactor between 6 and 24 months, depending on its location within the core.[2]

Moderator and Coolant

The use of natural uranium for fuel is different than most other reactor designs which require the use of enriched uranium (which means that its concentration of fissile uranium-235 has been enhanced). The reason that the uranium does not need to be enriched is due to the heavy water moderator which doesn't absorb as many neutrons as the commonly used light water does. In fact, heavy water as a moderator is 1700 times more efficient than light water![2]

Moderators work to slow down neutrons to speeds at which fissile elements can absorb them. This is required in nuclear reactors using uranium-235, and heavy water is one of the best moderators available. The moderator in the CANDU is kept at a relatively cool 70°C using a separate cooling system and is circulated through purification systems to ensure a high quality.[2] Learn more about neutron moderators on their page here.

The heavy water also acts as coolant in the CANDU; large amounts of heat are produced by the nuclear reactions, and the heavy water acts to transfer this heat away to an area where it can be made useful, at the same time as it cools the fuel down to safe temperatures. This useful area is known as the steam generator, and it acts as a heat exchanger.[2] The hot heavy water flows through tubes inside of the steam generator, which contains ordinary water. The heat from the heavy water boils the ordinary water into steam, which can then be sent to a turbine to generate electricity.

Steam Generator

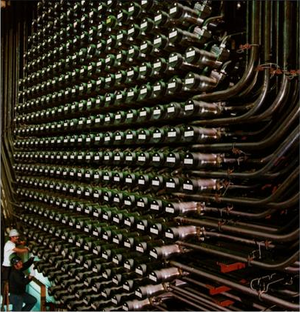

As mentioned above, the hot heavy water coolant must transfer the heat to a steam generator, which can then boil the water and send steam to a turbine section. The reason that a steam generator is used is due to the fact that the heavy water coolant is radioactive from being in direct contact with the reactor core. If this radioactive water were to come in contact with the turbine section it would pose a safety harm to workers and potentially the public, and increased costs would be required for shielding and containment in these sections.[2] The coolant flows through inverted tubes submersed within the steam generator, visible in Figure 3. There are hundreds of these tubes to maximize heat transfer between the systems.

On-line Refueling

On-line refueling in a CANDU reactor is a unique trait that is a major advantage over other reactors such as the pressurized water reactors and boiling water reactors. The CANDU has the ability to refuel while the reactor is still running whereas other reactors must shut down completely, lowering their capacity factor.[11]

This ‘on-power’ refueling can be accomplished because of the horizontal fuel loading design that allows for two remote fueling machines situated at opposite ends of a fuel channel. One fueling machine inserts new fuel bundles while the other receives the spent fuel bundles from the opposite end to be placed in the spent fuel storage bay (which is also done remotely).[2]

Reactor Configuration

The reactor configuration of a CANDU differs from other typical reactors, as fuel bundles are arranged horizontally rather than vertically, and are placed inside pressure tubes within a vessel (called the calandria).[2] The core of a CANDU reactor needs to be larger than comparable light water reactors however if it wants to achieve the same output capacity, and this due to the CANDU's use of natural uranium. This reactor configuration can be seen in Figure 4.

There are several hundred pressure tubes within a CANDU, with exact amounts differing between reactors. The coolant flows through these pressure tubes, each of which are enclosed within a calandria tube. The pressure tubes and calandria tubes are separated by spacers, in order to keep the coolant and the moderator separate. The space between these two tubes is filled with carbon dioxide, which acts as a thermal insulator in order to limit heat loss to the moderator.[2]

The reactor building that the CANDU is placed in is made of thick concrete and steel walls, with the walls of newer buildings also filled with hundreds of tonnes of water and thick steel balls to provide additional shielding.[2]

Safety Features

Passive Safety Features

The passive features in a CANDU include:

- Bending of the fuel channels in the event of overheating due to the CANDU's horizontal configuration, which will in turn slow down the rate of reaction. This is caused by the fact that the fuel rods are aligned in the ideal position for reactivity, and any bend in a fuel channel causes the reaction to slow because of wasted neutrons that do not hit their intended targets.[13]

- Control rods held up by electromagnets, which in the absence of a power signal are immediately released into the reactor core, making it impossible for the reaction to continue.[13] This is the primary shutdown system of a CANDU reactor.

Active Safety Features

- The injecting of neutron "poison" can be done to greatly diminish the nuclear reaction in the case of emergency.[2] This is done by pumps which are driven by a high pressure helium tank; When the reactor is required to shut down, valves between the high pressure helium tank and the gadolinium tanks are opened releasing the helium which drives the gadolinium into the reactor core.[13] Helium is appropriate for this job because it is doesn’t have the tendency to react.

- Equipped with an ample supply of light water so that in the event of a LOCA, cool light water can be quickly mixed with the overheating heavy water coolant to promptly bring the system back down to proper operating temperatures.[13] This is only used as a last resort as mixing the light and heavy water would mean having to re-purify the heavy water coolant.

For more information on CANDU reactors please visit www.nuclearfaq.ca or download a pdf of the e-book Half-lives.

References

- ↑ Wikimedia Commons [Online], Available: http://en.wikipedia.org/wiki/CANDU_reactor#/media/File:Bruce-Nuclear-Szmurlo.jpg

- ↑ 2.00 2.01 2.02 2.03 2.04 2.05 2.06 2.07 2.08 2.09 2.10 D. Jackson and H. Tammemagi, "CANDU, The Canadian Reactor" in Half-Lives: A Guide to Nuclear Technology in Canada 1st ed., Canada: Oxford University Press, 2009, ch.6, pp.75-90

- ↑ CANDU Owners Group, "CANDU Reactors: What is CANDU?," 2012. [Online]. Available: http://www.candu.org/candu_reactors.html

- ↑ IEA (2014), "World energy balances", IEA World Energy Statistics and Balances (database). DOI: http://dx.doi.org/10.1787/data-00512-en (Accessed February 2015)

- ↑ 5.0 5.1 World Nuclear Association. (June 6 2015). Nuclear Power in Canada [Online], Available: http://www.world-nuclear.org/info/Country-Profiles/Countries-A-F/Canada--Nuclear-Power/

- ↑ From https://canteach.candu.org/Pages/Welcome.aspx (July 9th, 2015)

- ↑ World Nuclear Association. (July 6 2015). Uranium Enrichment [Online], Available: http://www.world-nuclear.org/info/Nuclear-Fuel-Cycle/Conversion-Enrichment-and-Fabrication/Uranium-Enrichment/

- ↑ From nuclearfaq.ca (July 9th, 2015) http://www.nuclearfaq.ca/cnf_sectionF.htm.

- ↑ J. Gonyeau, "CANDU fuel and reactor specifics," 2005. [Online]. Available: http://www.nucleartourist.com/type/candu2.htm

- ↑ Wikimedia Commons [Online], Available: https://upload.wikimedia.org/wikipedia/commons/8/89/Nuclear_steam_generator.jpg

- ↑ J. Garland, "How and Why is a CANDU designed the way it is?," CANTEACH, 2003. [Online]. Available: https://canteach.candu.org/Content%20Library/20000101.pdf

- ↑ Introduction to CANDU 6- Part 3 Moderator, HTS, Heavy Water, by D.A. Meneley and Y.Q. Ruan. [Online], Available: https://canteach.candu.org/Image%20Library1/Forms/DispForm.aspx?ID=285&RootFolder=/Image%20Library1/19980103-Intro_to_CANDU6_China

- ↑ 13.0 13.1 13.2 13.3 CANDU 6 Program Team: Reactor Development Business Unit, CANDU 6 Technical Summary, 2005. Available: https://canteach.candu.org/Content%20Library/CANDU6_TechnicalSummary-s.pdf